Pressure Dynamics is a leading provider of specialist engineering solutions for the upstream oil and gas sector, delivering expertise in hydraulics, machining, cranes and lifting, and OEM product supply. We support offshore and onshore drilling operations, including jack-up rigs, semi-submersibles, drill ships, tender-assisted barges, and land-based gas drilling operations. Our tailored solutions enhance the performance, reliability, and safety of critical drilling and well control systems, ensuring efficient and uninterrupted operations.

Upstream and Drilling

With strategically located engineering teams, we provide rapid-response support to drilling contractors and operators, minimising downtime and optimising operational performance. Our expertise ensures equipment reliability, compliance with strict regulatory standards, and improved asset longevity across a wide range of offshore and onshore drilling environments.

Hydraulic Systems Engineering

We specialise in the design, maintenance, and optimisation of hydraulic systems that power critical drilling operations. Our expertise covers high-pressure well control systems, pipe-handling equipment, rig skidding systems, and BOP hydraulics, ensuring peak efficiency and operational safety in harsh offshore and onshore environments.

Our hydraulic services include system upgrades, troubleshooting, and predictive maintenance to prevent costly failures. We provide cylinder repairs, hydraulic power unit fabrication, and intervention solutions for drilling equipment, ensuring seamless performance in extreme conditions.

- Hydraulic Cylinder Design, Manufacture & Repair

- Hydraulic Power Unit (HPU) Design, Fabrication & Installation

- BOP Hydraulic Control System Overhaul & Testing

- Pipe-Handling & Iron Roughneck Hydraulic Systems

- Draw works & Top Drive Hydraulic Solutions

- Subsea Well Control & High-Pressure Hydraulic Systems

- Hydraulic Skidding Systems for Jack-Up Rigs

- Hydraulic System Troubleshooting & Upgrades

- Subsea Intervention tooling

Machining Services

Pressure Dynamics delivers precision machining and component refurbishment for critical downstream infrastructure. We support the repair and remanufacture of components used in refining processes, metering systems, compression units, and rotating equipment within petrochemical and LNG processing environments.

We offer reverse engineering of hard-to-source or obsolete parts, helping reduce lead times and costs. Our machining services ensure tight tolerances and high durability, even in corrosive and high-temperature process conditions.

- Custom Machining for Drilling Equipment Components

- Rotary Table & Drawworks Component Repair

- Mud Pump Cylinder Liner & Piston Manufacturing

- Specialist Parts Machining & Reverse Engineering

- Engineered Drawing Manufacture & Component Repair

- Large-Diameter Boring & Threading for Drill Components

- Top Drive & Kelly Spinner Component Fabrication

- Surface Coatings & Wear-Resistant Finishes

Cranes and Lifting Equipment

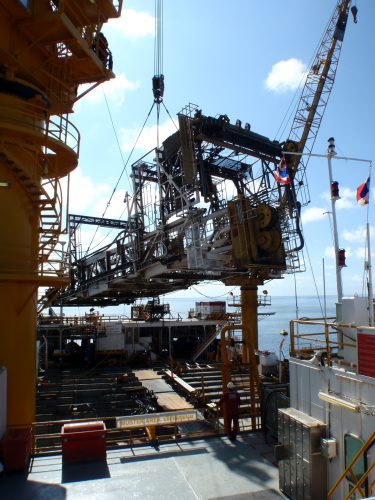

We provide specialist lifting and handling solutions tailored for offshore drilling rigs, jack-ups, and onshore drilling operations, ensuring safe and efficient movement of heavy drilling components. Our services cover lifting equipment installation, maintenance, certification, and load testing, keeping assets compliant with international safety standards.

We also support the replacement of major drilling components, such as BOP stacks, mud pumps, generators, and rig motors, minimising downtime and improving operational efficiency.

- Lifting Equipment Supply, Installation & Certification

- Maintenance & Refurbishment of Rig Cranes & Lifting Systems

- Drilling Components (BOPs, Mud Pumps, Generators, etc.)

- Load Testing & Compliance Inspections for Drilling Lifts

- Hoist and Winch System Repairs & Upgrades

- Pipe-Handling & Tubular Lifting Equipment Maintenance

- Mobile Crane Inspection, Testing & Maintenance

- Overhead & Gantry Crane Installation & Maintenance

OEM Product Supply

Pressure Dynamics supplies a wide range of OEM products for drilling operations, ensuring optimal system performance and durability in harsh offshore and onshore environments. We work closely with rig owners and drilling contractors to provide cost-effective solutions that integrate seamlessly into existing drilling infrastructure.

Our OEM product offerings include hydraulic components, filtration systems, pumps, seals, and custom-engineered solutions built to withstand the high-pressure and high-load conditions of drilling operations.

- Hydraulic Components & Filtration Systems

- Pumps, Seals & High-Performance Hoses

- Custom-Designed Hydraulic Solutions for Drilling Equipment

- OEM Hydraulic Cylinder & Actuator Supply

- Well Control Hydraulic Components & Manifolds

- Drilling Rig Lubrication Systems & Components

- Custom Hydraulic Power Units for Well Control Applications

- Specialist Hydraulic Fluids & Condition Monitoring Systems

Commitment to the Upstream & Drilling Industry

At Pressure Dynamics, we are committed to delivering high-performance engineering solutions that support the unique challenges of offshore and onshore drilling. Our expertise in hydraulics, machining, lifting, and system optimisation ensures that rig operations remain efficient, compliant, and operationally secure.

With a strong track record of supporting drilling contractors, rig operators, and well service providers, we help ensure safe and reliable drilling by providing tailored solutions that minimise downtime, reduce operational risks, and enhance performance. Whether supporting a jack-up, semi-sub, drillship, tender-assisted rig, or onshore gas drilling operation, our engineering expertise ensures every project is delivered with precision, reliability, and compliance.

Contact us today to discuss how we can support your upstream & drilling operations.