Precision-Engineered Hydraulic Solutions for Demanding Industries. Pressure Dynamics is a trusted leader in Original Equipment Manufacturing (OEM) for the hydraulics sector, with a proven track record across oil and gas, mining, defence, industrial and renewable markets. We deliver fit-for-purpose, high-performance equipment and components, engineered to meet the most rigorous operational and environmental demands. Our solutions are backed by a focus on safety, reliability, and technical excellence.

Original Equipment Manufacture (OEM) Services

We operate dedicated engineering and fabrication facilities across Perth, Karratha, Darwin and Queensland, enabling rapid delivery, tailored design, and end-to-end project control. Our multidisciplinary OEM team provides full lifecycle support—from design and modelling through to machining, assembly, factory acceptance testing and commissioning—ensuring every component integrates seamlessly with client systems.

OEM Capabilities and Services

Hydraulic Power Units

We design and manufacture custom Hydraulic Power Units (HPUs) to meet the demands of various sectors, including offshore, mining, and industrial processing.

Applications include subsea HPU modules for ROVs and control systems, car dumper HPUs for heavy-duty mine operations, and filter press HPUs for fluid separation and dewatering processes.

Each unit is engineered for the operating environment, incorporating high-performance components, logic-controlled functions, and robust enclosures.

Units can be mobile, containerised, or skid-mounted, with built-in diagnostics and remote monitoring options.All HPUs are engineered with quality components, integrated control systems, and tested to client operating conditions.

Sampling Stations

Sampling stations built for reliability, precision, and safety in demanding environments.

Our sampling stations are built for accuracy, reliability, and repeatability in harsh or high-pressure environments.

Available in manual or automated formats, each system is tailored to specific fluid characteristics, flow conditions, and sample handling requirements.

Designed to extract clean, representative samples without disrupting operations, they are commonly used in pipeline systems, process plants, and offshore skids.

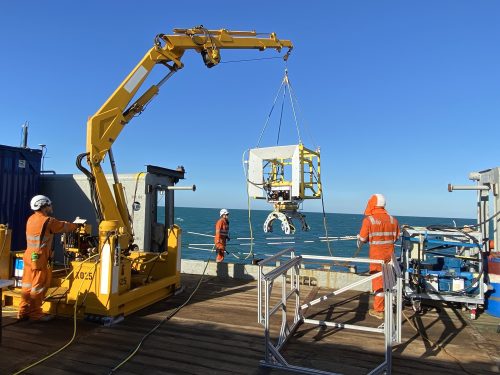

TUTUs (Topside Umbilical Termination Units)

TUTUs provide a critical interface between topside infrastructure and subsea umbilicals.

We engineer each unit for high-pressure service, accommodating hydraulic, chemical, and electrical terminations in compact, modular frames.

All units are designed for fast installation, reliable access, and long-term performance in offshore or harsh coastal environments.

Hose Assemblies & Fittings

Custom hydraulic hose assemblies and fittings manufactured to suit site-specific configurations, pressures and flow rates. We ensure all assemblies meet stringent quality standards for durability and safety.

Hydraulic Cylinders

We supply heavy-duty hydraulic cylinders, designed for strength, reliability, and serviceability.

From single-acting and double-acting to telescopic or displacement-type, all cylinders are custom-built to suit stroke, bore, and mounting configurations.

Designed for rebuilds and field servicing, each unit is pressure-tested and verified to meet or exceed operational requirements.

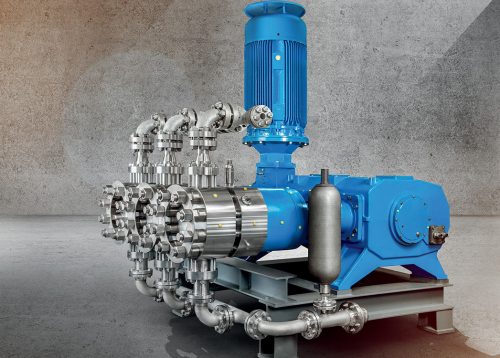

Hydraulic Components

We offer a full suite of hydraulic components, including pumps, motors, valves, filters, accumulators, and power packs.

These are available as standalone supply, system integration, or as part of turnkey solutions.

Our engineering team supports configuration, selection, and installation to suit both standard and demanding hydraulic applications.

Custom-Made Components

We machine, fabricate, and finish custom hydraulic and mechanical components in-house.

This includes piston rods, barrels, gland nuts, flanges, valve blocks, and mechanical couplings—either made to client drawings or reverse-engineered from samples.

Precision manufacturing and material selection ensure compatibility and long service life in critical applications.

Subsea Accumulator Modules

Our subsea accumulator modules are engineered for use in subsea control systems, emergency shutdown units, and chemical injection packages.

These systems are pressure-rated, DNV and API compliant, and configured for either fixed installation or ROV operation.

We offer standalone accumulators or integrated systems built into full subsea control modules, with fluid options including water glycol, synthetic oils, or methanol.

Flushing Rigs

We manufacture high-capacity flushing rigs designed to achieve ISO 4406 cleanliness standards.

Units are available in diesel or electric configurations and support flow rates ranging from 20 to 600 litres per minute.

Each system can be configured with onboard particle counters, heaters, chillers, and filtration modules for use during system commissioning, maintenance, or shutdowns.

Available for sale, rental, or complete project-based flushing services.

Custom Manifolds

We design and build hydraulic manifolds for both topside and subsea applications.

Each manifold is engineered to optimise space, flow efficiency, and maintenance access.

Whether it’s a block manifold for a mobile unit or a complex valve assembly for subsea distribution, we handle the full design, machining, assembly, and testing in-house.

We also support clients with reverse-engineered replacements and integration with sensors and logic control devices.

Why Choose Pressure Dynamics?

Pressure Dynamics is a trusted engineering partner to organisations who require solutions that go beyond off-the-shelf. Our commitment to technical rigour, attention to compliance, and proven delivery record across energy, defence, mining, and infrastructure makes us the first choice for companies operating in high-risk or mission-critical environments.

We are also a key partner in Australia for several other globally recognised OEMs, including Bosch Rexroth, Parker, LEWA, Stauff, and Hydac amongst others—giving our clients direct access to premium components, genuine spare parts, and trusted technical advice. Whether supplementing an existing fleet or equipping a site from the ground up, our integrated offering ensures that critical hydraulic work can be carried out efficiently and with confidence, using fit-for-purpose equipment backed by industry-leading support.