Modernising Legacy Systems for Enhanced Performance. Pressure Dynamics specialises in upgrading and retrofitting hydraulic systems to meet the evolving demands of the oil & gas, defence, mining, renewables, and industrial sectors. Our comprehensive services focus on enhancing system performance, reliability, and compliance with current standards, ensuring your operations remain efficient and competitive.

Hydraulic System Upgrades & Retrofitting

By integrating advanced technologies and components, we revitalise existing systems, extending their operational life and reducing the need for complete replacements. Our tailored solutions address obsolescence, improve energy efficiency, and align with modern safety and environmental regulations.

System Assessment & Engineering Analysis

Comprehensive Evaluation for Targeted Improvements

Our upgrade process begins with a thorough assessment of your existing hydraulic systems. We analyse performance metrics, identify inefficiencies, and evaluate component conditions to determine the most effective upgrade path. This detailed analysis ensures that enhancements are precisely targeted to deliver maximum benefits.

Utilising advanced diagnostic tools and simulation software, our engineers develop customised upgrade plans. These plans consider factors such as system load requirements, environmental conditions, and integration with existing infrastructure, ensuring seamless implementation and optimal performance.

- Performance benchmarking

- Component condition analysis

- System efficiency evaluation

- Failure mode and effects analysis (FMEA)

- Integration feasibility studies

- Customised upgrade planning

Component Upgrades & Technology Integration

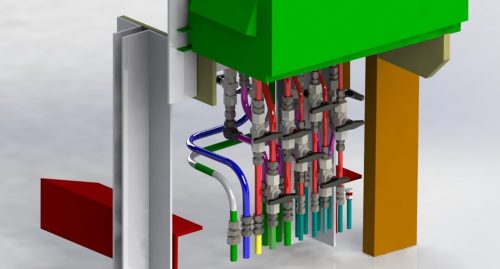

Incorporating Advanced Solutions for Enhanced Functionality. Upgrading key components within your hydraulic system can significantly improve performance and reliability. We offer a range of component upgrades, including pumps, valves, actuators, and control systems, selected to match your specific operational requirements and environmental conditions.

Our integration of modern technologies, such as electro-hydraulic actuators and advanced control systems, enhances system responsiveness and precision. These upgrades not only improve functionality but also contribute to energy savings and reduced maintenance needs. Our component upgrade services encompass:

- High-efficiency pump replacements

- Advanced valve installations

- Electro-hydraulic actuator integration

- Smart control system implementation

- Sensor and monitoring technology upgrades

- Energy-efficient component selection

Control System Modernisation

Enhancing System Intelligence and Responsiveness. Modern control systems offer improved accuracy, diagnostics, and adaptability. We specialise in retrofitting outdated control units with state-of-the-art programmable logic controllers (PLCs) and human-machine interfaces (HMIs), providing operators with intuitive control and real-time system feedback.

These modern control solutions enable predictive maintenance, remote monitoring, and seamless integration with enterprise systems. Upgrading your control systems ensures compliance with current industry standards and enhances overall operational efficiency. Our control system services include:

- PLC and HMI upgrades

- SCADA system integration

- Remote monitoring capabilities

- User interface customisation

- Compliance with industry protocols

Energy Efficiency & Environmental Compliance

Optimising Systems for Sustainable Operations. Improving the energy efficiency of hydraulic systems is crucial for reducing operational costs and environmental impact. Our upgrades focus on minimising energy consumption through the implementation of variable speed drives, efficient pump technologies, and system pressure optimisation.

We also ensure that upgraded systems comply with environmental regulations, including fluid containment standards and noise reduction requirements. Our solutions contribute to your organisation’s sustainability goals and regulatory compliance.

- Variable speed drive implementation

- System pressure optimisation

- High-efficiency pump integration

- Fluid containment enhancements

- Noise reduction measures

- Compliance with environmental standards

Safety Enhancements & Regulatory Compliance

Ensuring Safe and Compliant Operations. Safety is paramount in all industrial operations. We assess existing hydraulic systems for compliance with current safety regulations and implement necessary upgrades to mitigate risks. Our services include the installation of safety interlocks, emergency shutdown systems, and pressure relief devices.

By enhancing system safety features, we help protect personnel, equipment, and the environment. Our upgrades ensure that your hydraulic systems meet or exceed industry safety standards and regulatory requirements.

- Safety interlock installations

- Emergency shutdown system upgrades

- Pressure relief device implementation

- Risk assessment and hazard analysis

- Compliance auditing

- Operator safety training

Project Management & Implementation

Delivering Upgrades with Precision and Efficiency. Effective project management is essential for the successful execution of system upgrades. Our experienced project managers oversee all aspects of the upgrade process, from initial planning and procurement to installation and commissioning, ensuring minimal disruption to your operations.

We coordinate with all stakeholders to maintain clear communication and adhere to project timelines and budgets. Our structured approach guarantees that upgrades are completed efficiently and to the highest quality standards.

- Detailed project planning

- Procurement and logistics coordination

- Installation supervision

- System testing and commissioning

- Documentation and reporting

- Post-upgrade support and maintenance

Partner with Pressure Dynamics for Expert Hydraulic System Upgrades

With a commitment to excellence and a focus on tailored solutions, Pressure Dynamics is your trusted partner for hydraulic system upgrades and retrofitting. Contact us to learn how we can enhance the performance, safety, and efficiency of your hydraulic systems.