At Pressure Dynamics, we specialise in complete hydraulic repair and troubleshooting services that ensure your equipment remains safe, reliable, and fully operational. Our team is equipped to handle everything from emergency breakdowns to detailed investigations into performance inefficiencies, helping reduce costly downtime and extend asset life.

Hydraulic Repairs and Troubleshooting

With a deep understanding of hydraulic systems used in offshore, mining, Defence, industrial, and infrastructure environments, we apply rigorous inspection, maintenance, and engineering expertise. Whether working on-site or in our dedicated workshops, our approach is responsive, technical, and tailored to your operational goals.

Hydraulic System Diagnostics

Understanding the root cause of hydraulic faults begins with accurate and efficient diagnostics. Our team uses advanced testing equipment to analyse system pressures, flows, temperatures, and fluid quality, enabling early identification of potential failures and performance bottlenecks.

This proactive approach supports cost-effective repairs and targeted maintenance strategies. From fluid contamination to component misalignment, our diagnostics process is detailed, data-driven, and essential to improving the longevity and reliability of your system.

- Advanced System Analysis

- Fluid Condition Monitoring

- Pressure and Flow Testing

- Thermal Imaging

- Vibration and Noise Assessment

- Detailed Technical Reporting

Component Repair and Overhaul

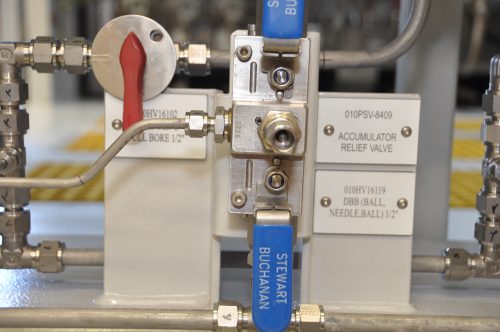

Hydraulic components such as cylinders, motors, pumps, and valves are subject to intense wear. At Pressure Dynamics, we offer in-depth repair and overhaul services designed to return critical components to optimal operating condition, often extending beyond original OEM tolerances.

Our workshops are fully equipped for dismantling, inspection, machining, surface treatment, resealing, and final testing. Whether you’re dealing with leaking cylinders or inefficient pumps, our component rebuilds deliver performance and durability in line with modern operational demands.

- Cylinder Strip and Rebuilds

- Pump and Motor Refurbishment

- Valve Block Repairs

- Precision Machining

- Seal and Bearing Replacement

- Surface Reconditioning

On-Site Maintenance and Support

We understand the value of uptime. Our field service teams are trained and equipped to support breakdown recovery, system troubleshooting, and maintenance planning directly at your site, reducing the time and cost associated with transporting heavy equipment off-site.

Services include mobile diagnostics, minor repairs, flushing, and operator training. All work is completed to the highest safety and technical standards, with comprehensive reports provided to help clients make informed decisions on equipment condition and maintenance schedules.

- Rapid Response Call-Outs

- Scheduled Maintenance Support

- Mobile Workshop Services

- Hydraulic System Flushing

- Operator and Technician Training

- Inspection and Reporting

System Optimisation and Upgrades

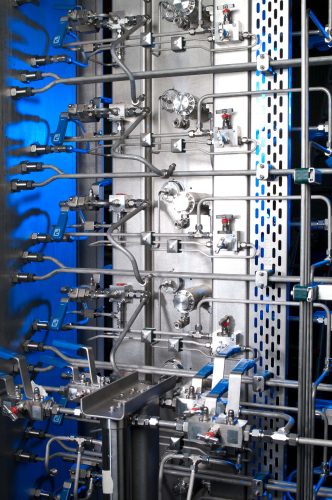

Hydraulic systems can often be enhanced through upgrades that improve efficiency, safety, and control. We assess existing installations and recommend practical improvements such as upgrading control systems, resizing components, and refining energy usage.

Whether supporting a capital project or retrofitting an ageing system, our engineering team delivers tailored upgrades that are aligned with industry standards. Our experience in critical industries ensures that modifications are reliable, maintainable, and effective in demanding environments.

- Efficiency Assessments

- Control System Modernisation

- Capacity Upgrades and Reverse Engineering

- Safety Enhancements

- Custom Engineering Solutions

- Standards Compliance Upgrades

Equipment Hire & Product Sales

Effective hydraulic repair and troubleshooting relies not only on technical expertise but also on having the right equipment available when and where it’s needed. Pressure Dynamics offers a comprehensive range of hydraulic and fluid management systems for both hire and purchase, supporting everything from emergency breakdowns and routine maintenance to shutdowns and long-term operational needs. Each item is selected for its reliability in demanding conditions and is supported by our expert engineering, commissioning, and service teams to ensure safe and seamless operation in the field.

We are also a partner in Australia for several globally recognised OEMs, including Bosch Rexroth, Parker, LEWA, Stauff, and Hydac—giving our clients direct access to premium components, genuine spare parts, and trusted technical advice. Whether supplementing an existing fleet or equipping a site from the ground up, our integrated offering ensures that critical hydraulic work can be carried out efficiently and with confidence, using fit-for-purpose equipment backed by industry-leading support.

- Hydraulic Power Units (HPUs)

- Flushing & Heating Systems

- Instrumentation & Data Logging Kits

- Directional Valves and Manifolds

- Pumps, Motors & Accumulators

- Custom Trolley-Mounted Assemblies

Partner with Pressure Dynamics for Expert Hydraulic Repairs & Troubleshooting

At Pressure Dynamics, we specialise in complete hydraulic repair and troubleshooting services to keep your equipment safe, reliable, and fully operational. From emergency breakdowns to performance investigations, our expert team works to reduce costly downtime and extend asset life.

With deep expertise across offshore, mining, Defence, industrial, and infrastructure sectors, we combine rigorous inspection, maintenance, and engineering know-how. Whether on-site or in our dedicated workshops, our approach is fast, technical, and aligned with your operational goals.