Protecting System Integrity Across Critical Industries. Pressure Dynamics delivers comprehensive hydraulic fluid management services—including filtration, flushing, and contamination control—tailored to the oil & gas, defence, mining, renewables, and industrial sectors. Our solutions are designed to maintain fluid cleanliness, enhance system reliability, and extend equipment lifespan, ensuring consistent performance in high-risk environments.

Hydraulic Filtration, Flushing & Fluid Management

Using advanced equipment and proven methodologies, we address challenges such as particulate ingress, water contamination, and varnish formation. Our proactive fluid management strategies help prevent unplanned outages, reduce maintenance costs, and ensure ongoing compliance with industry and OEM standards.

Fluid Cleanliness & Contamination Control

Ensuring Optimal Performance Through Clean Fluids. Maintaining fluid cleanliness is critical to the efficient operation and longevity of hydraulic systems. Contaminants such as particulates, water, and air can accelerate wear, reduce system efficiency, and increase the risk of failure. Our fluid cleanliness programmes are designed to meet stringent ISO cleanliness codes, protecting equipment from avoidable degradation.

We deploy best-in-class filtration technology and contamination monitoring tools to keep hydraulic fluids within target specifications. By addressing contamination proactively, we help our clients lower their total cost of ownership while increasing asset reliability and operational safety.

- Fluid sampling and analysis

- Contamination control strategies

- Water removal and dehydration

- Air and gas elimination

- Varnish and sludge mitigation

- Cleanliness certification and reporting

High-Velocity Flushing & System Decontamination

Restoring System Health Through Effective Flushing. Over time, hydraulic systems can accumulate built-up debris, scaling, or contaminants from component failure or fluid breakdown. High-velocity flushing is a vital process to remove internal contamination and restore fluid pathways, especially during commissioning, repairs, or major shutdowns.

We tailor each flushing operation to system requirements, using bespoke setups and filtration rigs to achieve target ISO codes. Final flushing is verified through inline particle counters and fluid analysis, with results documented and certified for compliance and assurance.

- High-velocity oil flushing

- System decontamination procedures

- Flushing of new and existing systems

- Verification of cleanliness levels

- Documentation and certification

- Compliance with industry standards

Fluid Conditioning & Lifecycle Management

Maximising Fluid Life and System Efficiency. Through careful conditioning and monitoring, we help extend fluid life, reduce waste, and protect expensive hydraulic components. Our services are tailored to fluid type, operating conditions, and OEM recommendations—ensuring the correct chemical balance, cleanliness level, and temperature are maintained throughout the fluid’s service life.

We support clients with offline filtration, dehydration, additive monitoring, and thermal control, helping to prevent oxidation, varnish formation, and wear. Regular lifecycle assessments ensure hydraulic systems continue to run within safe and efficient parameters.

- Offline filtration (kidney loop)

- Water removal and dehydration

- Additive analysis and replenishment

- Thermal management

- Fluid property monitoring

- Scheduled maintenance programmes

Mobile Equipment & On-Site Services

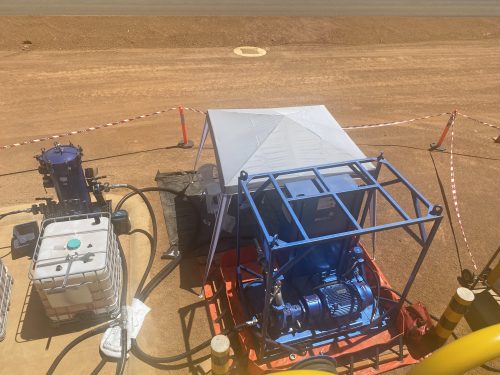

Flexible Delivery Wherever You Operate. We understand the importance of rapid, responsive service—particularly during shutdowns, construction campaigns, or breakdown recovery. Pressure Dynamics maintains a fleet of mobile flushing and filtration units, along with experienced technicians capable of delivering full-service solutions at site.

Our self-contained mobile rigs are engineered for safe, efficient deployment in remote, offshore, or space-restricted locations. On-site services are backed by real-time fluid analysis and expert technical support, ensuring minimal disruption to your operations.

- Portable filtration and flushing units

- On-site fluid testing and sampling

- Emergency response mobilisation

- Custom service packages

- Rapid deployment and setup

- Integration with existing systems

Diagnostic Testing & Fluid Analysis

Data-Driven Decisions for Predictive Maintenance. Fluid analysis plays a central role in predictive maintenance and early fault detection. Our diagnostic testing services provide insight into the condition and integrity of hydraulic fluids—supporting proactive maintenance strategies and long-term asset protection.

We offer both in-house laboratory analysis and on-site testing to assess cleanliness, fluid chemistry, degradation, and contamination. Results are interpreted by experienced engineers who provide actionable recommendations and benchmarking against industry standards.

- Particle count analysis

- Water content measurement

- Viscosity and acidity testing

- Spectrometric analysis

- Thermal and oxidative stability assessment

- Customised reporting and recommendations

OEM-Integrated Solutions & Equipment Supply

Trusted Partnerships for Long-Term Performance

As one of the key Australian providers for globally recognised brands such as Bosch Rexroth, Parker, Stauff, and Hydac, we offer unmatched access to quality hydraulic components and technical expertise. Our partnerships ensure that all filtration and fluid systems are backed by OEM warranties, specifications, and traceability.

This OEM alignment allows us to design, supply, and support integrated systems built on genuine components—ensuring long-term reliability, compliance, and simplified lifecycle management.

- Genuine filtration and fluid handling products

- System design and component selection

- OEM-certified commissioning support

- Technical documentation and training

- Spare parts and consumables supply

- OEM compliance and warranty protection

Partner with Pressure Dynamics for Hydraulic Fluid Management Done Right

Our filtration, flushing, and fluid management services protect your most critical assets, enhance operational uptime, and ensure compliance with global best practices. Get in touch with our team to learn how we can support your site’s hydraulic health.