At Pressure Dynamics, we deliver comprehensive hydraulic engineering and design services tailored to the unique and often extreme operational demands of sectors such as Mining, Defence, Oil & Gas, Subsea, Industrial Manufacturing, and Renewable Energy. Our solutions are grounded in decades of practical experience, backed by rigorous engineering discipline, and informed by evolving industry requirements and international standards.

Precision-Engineered Hydraulic Solutions Across Industries

Whether for critical lifting applications on offshore platforms, advanced hydraulic actuation for fixed mining plant, or precision control systems in subsea maintenance, our engineering approach focuses on reliability, safety, maintainability, and total lifecycle value. From greenfield developments to complex brownfield retrofits, we integrate hydraulic system expertise with advanced digital tools to design fit-for-purpose solutions that meet compliance, budget, and operational uptime goals.

Engineering, Drafting, Modelling & Simulation

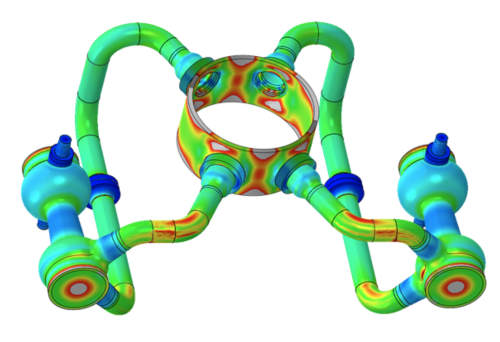

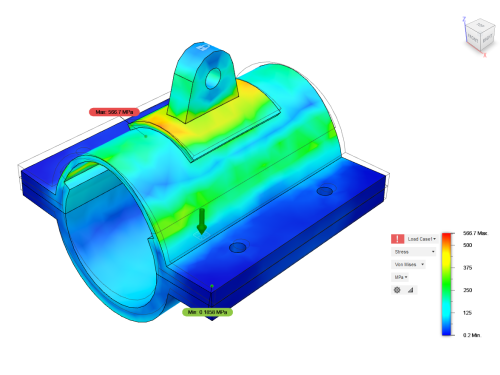

Pressure Dynamics’ engineering team uses advanced simulation, 3D modelling, and analytical tools to visualise and optimise hydraulic systems before a single component is built. These services are particularly valuable for clients operating in high-risk environments where failure is not an option—such as subsea production, military platforms, and automated manufacturing lines.

We develop digital representations and functional models that allow for real-time performance evaluation, fault diagnosis, and predictive maintenance forecasting. These tools reduce design rework, increase first-time-right outcomes, and ensure our systems are efficient, safe, and tuned to the operational environment.

- 3D CAD Modelling

- Finite Element Analysis (FEA)

- Computational Fluid Dynamics (CFD)

- Dynamic System Simulation.

- Digital Twin Development

- System Layout and Interface Definition

Original Equipment Manufacture (OEM)

We provide full-scope OEM services for custom hydraulic and mechanical systems—from concept to commissioning.

Our in-house capability spans engineering design, fabrication, assembly, testing, and documentation.

We build high-reliability equipment for harsh, remote, and regulated environments, including mining, oil and gas, renewables, and defence.

Leveraging our integrated workshop, engineering office, and supply chain network, we reduce project risk and lead time by keeping design, fabrication, assembly, and testing under one roof. All equipment is built to meet or exceed Australian and international design codes, and we can provide traceable documentation packages suitable for defence or high-integrity infrastructure.

- Custom Hydraulic Power Units (HPUs)

- Hydraulic Cylinders and Actuators

- Integrated Control Systems

- Skid-Mounted Systems

- Subsea Systems

- Compliance with Industry Standards

Reverse Engineering, Obsolescence & System Optimisation

We help clients extend the life of legacy or undocumented hydraulic systems through reverse engineering, performance analysis, and system upgrades. This is essential for assets in offshore oil & gas, naval operations, and ageing industrial facilities where OEM support may no longer exist or spare parts are obsolete.

Our team captures physical and functional data through scanning, disassembly, and analysis, then reproduces components with improved materials, geometry, or tolerances. For complete systems, we offer optimisation recommendations that can reduce operating costs, increase efficiency, and simplify maintenance.

- Component Analysis and Redesign

- System Upgrades

- Control upgrades

- Obsolescence Management

- Performance Optimisation

- Documentation and Technical Support

Lift and Structural Engineering

Lifting operations—whether offshore, in shipyards, mining plants, or wind energy construction—demand absolute confidence in the engineering behind the equipment. Pressure Dynamics provides engineered lifting solutions that combine structural integrity, precise control, and load-specific rigging design. From fixed crane supports to temporary lifting frames, we ensure that your lifting systems are structurally sound, legally compliant, and engineered for practical deployment in-field.

Our lift and structural services support new installations, equipment upgrades, and critical lifting scopes for major maintenance events. We perform advanced analysis of load paths, structural stability, and rigging safety, helping our clients mitigate risk during complex lifts in confined or high-exposure environments.

- Custom Engineered Lifting Solutions

- Structural Analysis AS, DNV, and EN codes.

- Rigging Design

- Load Testing and Certification

- Integration with Existing Systems

- Engineering adjustments

Why Choose Pressure Dynamics?

Pressure Dynamics is a trusted engineering partner to organisations who require solutions that go beyond off-the-shelf. Our commitment to technical rigour, attention to compliance, and proven delivery record across energy, defence, mining, and infrastructure makes us the first choice for companies operating in high-risk or mission-critical environments.

- Industry Expertise – Deep experience in hazardous, remote, and highly regulated sectors.

- Customised Solutions – Engineered-to-order systems that precisely fit your application.

- Quality Assurance – Integrated testing, inspection, and documentation from concept to commissioning.

- Comprehensive Support – We stay involved post-delivery with service, training, and lifecycle upgrades.