Pressure Dynamics provides expert lift planning, engineered lifting solutions, and complex rigging execution for offshore and onshore critical lifting operations. Whether mobilising major equipment, installing structural components, or executing non-routine lifts in constrained environments, we deliver safe, compliant, and efficient lifting operations backed by detailed engineering and multi-skilled field teams.

Lift Plan and Lifting Engineering

Our in-house engineers and lifting supervisors work alongside client representatives, OEMs, and classification bodies to develop custom lift plans and method statements for one-off, repeat, or campaign-based lifting scopes. From concept through to execution, our approach reduces risk, ensures compliance with relevant industry standards, and enables successful project delivery in complex environments.

Engineered Lift Planning

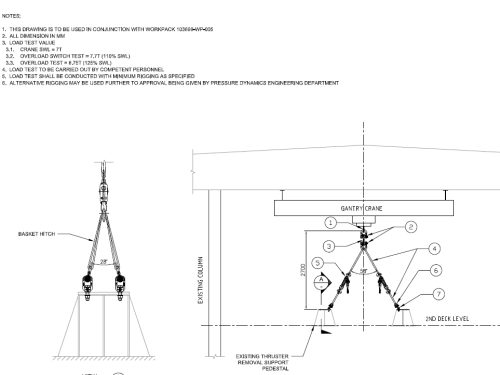

Every lift begins with a detailed engineering study that defines load characteristics, environmental conditions, crane capacities, and rigging configurations. Pressure Dynamics prepares full lifting plans, drawings, and risk assessments for simple to highly complex lifts –ensuring all technical, safety, and operational aspects are addressed before mobilisation.

- Lift studies including load weight, dimensions, centre-of-gravities and lifting points

- Lifting equipment selection and specification

- Load path, exclusion zone, and deck loading analysis

- Crane capacity analysis and selection

- Method statements, JHAs, and contingency planning

- Personnel roles, responsibilities and competencies

Complex Rigging Design & Equipment Supply

We provide complete rigging solutions for unconventional, heavy, or high-risk lifts including asymmetric loads, awkward geometries, and high-value equipment. Our team designs custom rigging arrangements and supplies all certified rigging gear, supported by competent riggers and lifting supervisors.

- Custom rigging configuration design with 3D lift visualisation

- Spreader bars, equaliser beams, soft slings, and rigging gear selection

- Dynamic load calculations for offshore and suspended lifts

- Tagline, snatch block, and rotation control planning

- Sling angle and shackle sizing optimisation

- Supply of certified rigging equipment, load cells, and lift aids

Lift Engineering & Structural Validation

In collaboration with our engineering division, we ensure all lifting structures and interfaces are validated for the imposed loads. This includes skid base, grillage, lifting lugs, padeyes, deck inserts, and temporary structures. We also design and certify custom lifting devices when required.

- Finite Element Analysis (FEA) of lift frames, padeyes, and lugs

- Structural verification of deck, platform, and support systems

- Lifting beam and rigging frame design and fabrication

- Grillage and sea fastening design

- Temporary lift structure and bracing design

- Load test certification and engineering sign-off

Lift Execution & Supervision

Our experienced lifting teams execute critical lifts safely and efficiently under the direction of qualified lifting supervisors. We control every stage of the lift including pre-lift briefings, dynamic conditions monitoring, communication protocols, and shutdown coordination. All lifts are completed to plan, with as-built documentation and client sign-off.

- Mobilisation of multi-skilled rigging and lifting teams

- Pre-lift checks, toolbox talks, and role assignments

- Tagline and load orientation control during hoisting

- Weather monitoring and environmental hold points

- Lift execution in live or shutdown environments

- Post-lift reporting and lessons learned

Lifting Documentation & Compliance

All lifting scopes are supported by fully traceable documentation, aligned with operator, OEM, and classification requirements. Our engineers prepare complete lift packs including certifications, load charts, rigging schematics, and execution procedures for audit, review, and historical records.

- Lift plan documents including calculations and technical drawings

- Rigging layout diagrams and sling tables

- Crane capacity verification and certification

- Material certification for rigging and lift devices

- Risk assessments, JHAs, and SIMOPS integration

- Post-lift records and operator handover documentation

Your Partner for Engineered Lifting Operations

Pressure Dynamics delivers engineered lifting solutions across the energy, infrastructure, and marine sectors. From heavy component lifts and crane changeouts to shutdown rigging scopes and high-precision lifts, our experience, systems, and people ensure safety, certainty, and quality in every lift.

Contact us today to discuss your complex lifting requirements.