Pressure Dynamics provides turnkey crane installation and commissioning services, supporting clients with the safe deployment, assembly, and operational start-up of new pedestal, davit and overhead cranes across energy, mining and defence assets. Our multidisciplinary teams manage the entire process from pre-installation planning and logistics through to final load testing and handover, ensuring compliance with OEM, class, and operator requirements.

Crane Installation & Commissioning

Whether installing replacement cranes as part of brownfield programs or supporting newbuild and major modification projects, we bring deep technical expertise in mechanical, hydraulic, and lifting system integration. Our field-proven methodology ensures reliable, efficient, and fully certified crane installations—ready for operational use in the most demanding environments.

Pre-Installation Engineering & Logistics

Effective crane installation begins with detailed planning, interface validation, and coordination with logistics and project stakeholders. Pressure Dynamics provides comprehensive front-end engineering and logistics support to ensure a smooth mobilisation and efficient crane integration. We conduct site surveys, lift studies, clash checks, and installation sequencing to reduce installation time and minimise installation risks.

- Pre-installation site surveys to facilitate detailed planning activities

- Interface checks with structural, mechanical, and hydraulic systems

- Transport planning and packaging for lifting operations and mobilisation

- Engineered lift plans and crane-on-crane studies

- Risk assessments, method statements, and job hazard analysis

- Coordination with rigging and operator teams

Mechanical Installation & Assembly

Our mechanical teams handle the full assembly and installation of crane structural and mechanical components. Using certified rigging and mechanical procedures, we ensure all structural and rotating components are installed to OEM tolerances and torqued, aligned and pinned to specification.

- Crane structural component installation with bolting and alignment checks

- Hoist, slew/travel and luffing assembly installations

- Installation of ladders, guards, handrails, and walkways

- Final torquing of fasteners to OEM and class specifications

- Lubrication and mechanical bedding-in procedures

- Alignment verification of hoist, slew/travel and luffing systems

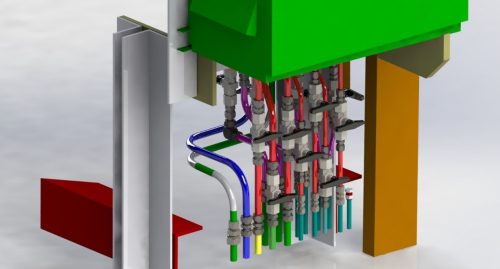

Hydraulic Connection & Integration

Pressure Dynamics’ hydraulic specialists manage all crane fluid power connections and commissioning. Our team ensures that HPU’s, valves, and manifolds are fully integrated and operating within pressure and flow tolerances. We install and terminate hoses, flush hydraulic lines, charge accumulators, and validate all fluid systems under load.

- Hydraulic hose routing, terminations, and clamping

- Oil flushing and filtration of new hydraulic circuits

- Pre-charge of accumulators and hydraulic pressure calibration

- Functional testing of hoisting, slewing/travel and luffing functions

- HPU integration and fluid cleanliness validation

- Leak, vibration, and back-pressure testing

Electrical Connection & Integration

Pressure Dynamics’ electrical team manage all crane electrical connections and commissioning. Our team ensures that power distribution panels, motor control centres (MCC’s), and variable frequency drives (VFD’s) are correctly installed for precise hoisting and travel control. These systems also integrate programmable logic controllers (PLCs), safety interlocks, and load monitoring systems to ensure reliable, automated, and safe crane operation.

- Electrical cable routing, terminations, and securing

- Electrical component installation

- Continuity and resistance testing

- PLC and SLI/LMI integration

- Functional testing and calibration of control and safety systems

- Hazardous area equipment installation

Proof Load Testing & Certification

As part of final commissioning, we execute controlled proof load testing in accordance with OEM and class requirements. Our team manages the full load testing process including lift planning, rigging, water bag or solid weight configuration, and third-party witnessing as required. All results are recorded, verified, and submitted with a complete certification package.

- Site acceptance and functional testing

- Load testing lift plan development

- Supply and rigging of calibrated load test equipment

- Execution of static and dynamic proof load testing

- Calibration of load monitoring systems

- Witnessing by class or independent third-party surveyors, as required

Documentation, Handover & Operator Support

Upon successful installation and testing, we deliver a comprehensive documentation and handover package. This includes updated maintenance schedules, operational readiness documentation and OEM service data. We also support onsite training and onboarding of operator teams to ensure a seamless transition to full use.

- Installation and commissioning report with photographic evidence

- Updated maintenance and inspection requirements

- Generation of test certificates and compliance reports

- Load test and LMI certification

- OEM spare parts list and technical documentation

- On-site operator familiarisation training

Your Crane Installation Partner

Pressure Dynamics is trusted by operators across Australia and internationally to install and commission critical lifting systems safely and efficiently. From newbuilds to crane replacements, we provide a complete solution—delivered by experienced, multi-skilled teams ready to mobilise worldwide. With end-to-end engineering, execution, and certification, we make crane deployment simple, safe, and compliant. Contact us today to discuss your crane installation and commissioning requirements.