Pressure Dynamics delivers comprehensive crane inspection, testing, and engineering services, supporting asset integrity, operational compliance, and lifecycle management across all crane types. We provide full-scope inspection campaigns incorporating visual, structural, hydraulic, mechanical, and non-destructive testing (NDT) using both conventional and advanced access and monitoring technologies.

Crane Inspection, Testing and Engineering

Working in partnership with our certified NDT sister companies and in house rope access teams, we deliver efficient, high-quality inspection programs that minimise disruption to operations. Whether supporting periodic inspection cycles, class compliance, or detailed fault investigation, our multidisciplinary approach ensures accuracy, traceability, and safety from start to finish.

Visual, Structural & Mechanical Inspection

Our inspection specialists conduct detailed evaluations of critical crane structures and components, identifying wear, damage, corrosion, or fatigue across the full lifting system. Incorporating OEM recommendations, Australian and international standards, and industry best practices, we deliver complete assessments with traceable inspection data and actionable recommendations.

- General and close visual inspections of crane structural components

- Mechanical component inspection (brakes, gearboxes, hoists, sheaves)

- Corrosion mapping, coating breakdown assessment, and wear tracking

- Weld inspections and distortion monitoring on critical structures

- Functional testing of all crane operations and safety/control systems

- Provision of inspection reports with identified defects, photographic evidence and recommendations for remediation

IRATA Rope Access & Remote Inspection

To reduce crane downtime and avoid scaffolding costs, our IRATA-certified technicians perform inspections via rope access and elevated rigging. This allows safe and efficient access to booms, jibs, runway and bridge beams, cabs, towers, and underslung components—often while the asset remains in operation.

- IRATA rope access inspections of booms, kingposts, and lifting points

- Hard-to-reach bolt, weld, and pin inspections without intrusive access

- Tertiary platform and structural frame inspections

- Rescue-trained technicians for complex or confined access areas

- Integrated inspection teams with mechanical and NDT capabilities

- Pre-cleaning and light mechanical removal of corrosion or coatings

NDT & Specialist Testing Methods

Through our certified sister companies, we offer a full suite of conventional and advanced non-destructive testing techniques to support crane structural integrity, including weld testing, wire rope analysis, and fatigue investigation. All inspections are carried out in compliance with industry standards by qualified technicians (PCN, CSWIP).

- Magnetic Particle Testing (MT) and Dye Penetrant (PT) for welds and components

- Ultrasonic Testing (UT) for thickness, crack detection, and material loss

- Eddy Current Testing (ECT) for surface cracks and heat-affected zones

- Wire rope electromagnetic and visual inspection

- Load-bearing component inspection under dynamic conditions

- Radiographic Testing (RT) where required for structural welds

Drone & Digital Inspection Technologies

For high-value assets or limited-access environments, we deploy UAV drone inspections and 3D scanning to deliver accurate, repeatable inspection outcomes with minimal disruption. We also generate digital twins of crane structures for ongoing monitoring and lifecycle asset management.

- UAV inspections of booms, sheaves, wire rope systems, and structure topsides

- High-resolution imagery and thermal/infrared analysis

- 3D laser scanning of pedestal and structural components

- Change detection through repeat surveys and model comparisons

- Integration with digital twin platforms for lifecycle analysis

- Defect tagging and visual inspection overlays within 3D models

Load Testing & Functional Validation

In addition to inspection, we provide full load and operational testing services, validating crane performance under actual lifting conditions. Our team supplies calibrated load testing equipment, executes test lifts, and documents performance data in accordance with OEM and operational requirements.

- Static and dynamic proof load testing using water bags or solid test weights

- Brake stall testing and hoisting system testing under load

- Slewing, luffing, boom extension, and cross/long travel testing under load

- Load Moment Indicator (LMI) and safety system testing and verification

- Third-party witnessing and class sign-off where required

- Generation of test certificates and updated load charts

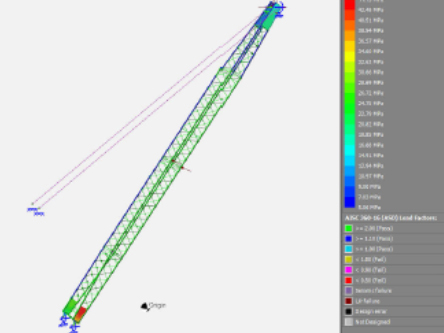

Engineering Analysis & Inspection Reporting

Beyond field inspections, Pressure Dynamics provides engineering interpretation and lifecycle analysis of crane inspection data. We support clients with repair scoping, redesign recommendations, and fitness-for-service decisions based on field data, modelling, and structural assessment tools.

- Engineering review of inspection and test results

- Fatigue life assessments and structural capacity calculations

- Reverse engineering and remediation design where required

- Fitness-for-service assessments and remaining life modelling

- Repair and modification engineering including welding procedures

- Integration with client CMMS and digital asset systems

Your Crane Inspection Partner

Pressure Dynamics supports operators with complete crane inspection, testing, and engineering services across Australia and international markets. Whether part of a planned maintenance program or a targeted integrity review, we bring deep technical experience and cross-functional capability—backed by rope access, NDT, and advanced inspection technology.

Contact us today to plan your next crane inspection campaign.